|

|

Phone(s):

437-324-4766

|

31 Taylor Blvd.,

Port Perry Ontario L9L 0B7 |

Astec - Peterson 4310B Highwalker Drum Chipper |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

|

Specifications

|

||||||||||||||||||||||||||

|

Description

|

||||||||||||||||||||||||||

|

TRACKS

|

||||||||||||||||||||||||||

|

Tracks

|

||||||||||||||||||||||||||

|

CHIPPER

|

||||||||||||||||||||||||||

|

Chipper

|

||||||||||||||||||||||||||

|

WEIGHTS

|

||||||||||||||||||||||||||

|

Weights

|

||||||||||||||||||||||||||

|

FEATURES

|

||||||||||||||||||||||||||

|

Features

|

||||||||||||||||||||||||||

|

DOWNLOADS

|

||||||||||||||||||||||||||

|

Downloads

|

||||||||||||||||||||||||||

|

DIMENSIONS

|

||||||||||||||||||||||||||

|

Dimensions

|

||||||||||||||||||||||||||

|

POWERTRAIN

|

||||||||||||||||||||||||||

|

Powertrain

|

||||||||||||||||||||||||||

|

PRODUCTION

|

||||||||||||||||||||||||||

|

Production

*Actual production output may vary due to moisture content, material density and size, support equipment, and equipment options. Production rates are based on operating 50 minutes per hour. |

||||||||||||||||||||||||||

|

FEED SYSTEM

|

||||||||||||||||||||||||||

|

Feed_System

|

||||||||||||||||||||||||||

|

SYSTEM CONTROLS

|

||||||||||||||||||||||||||

|

System_Controls

|

||||||||||||||||||||||||||

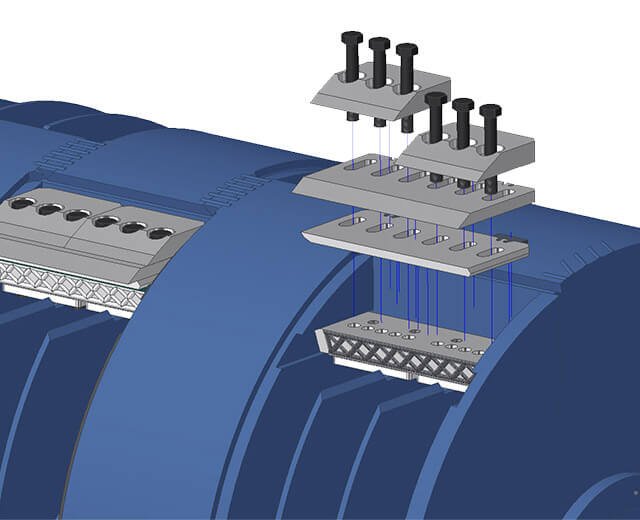

Knife Assemblies at the Heart of the Chipper

Knife Assemblies at the Heart of the Chipper Select from 6- or 12-Pocket Drum

Select from 6- or 12-Pocket Drum Discharge Spout Options

Discharge Spout Options Superior Product Sizing

Superior Product Sizing